Plastic Injection Molding for Beginners

Wiki Article

A Biased View of Plastic Injection Molding

Table of ContentsRumored Buzz on Plastic Injection MoldingGetting My Plastic Injection Molding To WorkThe Best Guide To Plastic Injection MoldingAll About Plastic Injection Molding

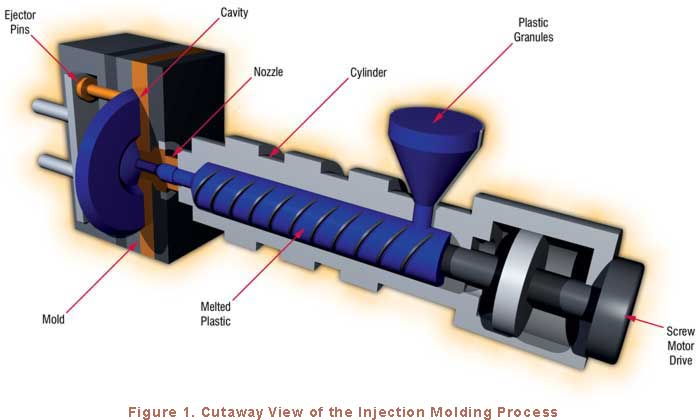

The sequence of occasions during the injection mould of a plastic component is called the injection moulding cycle. The cycle begins when the mould shuts, followed by the injection of the polymer right into the mould cavity. When the dental caries is filled, a holding pressure is preserved to make up for material shrinking.

This creates the screw to retract as the next shot is prepared. Typically, the shot part of the moulding procedure was done at one consistent pressure to fill and pack the tooth cavity.

When the tooth cavity is 98% complete, the equipment switches over from velocity control to pressure control, where the cavity is "packed out" at a continuous pressure, where adequate speed to reach preferred pressures is needed. This lets workers control part dimensions to within thousandths of an inch or better. Different types of shot moulding procedures [modify] Although the majority of shot moulding procedures are covered by the standard procedure description above, there are several essential moulding variations consisting of, yet not restricted to: An even more detailed listing of injection moulding processes might be located below: Refine fixing [ modify] Like all commercial processes, shot molding can create flawed components, also in toys.

The Single Strategy To Use For Plastic Injection Molding

Tests are typically executed before full manufacturing runs in an initiative to predict flaws and also determine the proper requirements to use in the shot process.: 180 When filling up a brand-new or strange mould for the very first time, where shot size for that mould is unidentified, a technician/tool setter might perform a trial run before a full manufacturing run. plastic injection molding.Once they attain this, they use a small amount of holding pressure as well as boost holding time till gateway scorn (solidification time) has occurred. Gate scorn time can be established by increasing the hold time, and after that evaluating the component. plastic injection molding. When the weight of the component does not alter, the gateway has actually iced up and also no even more product is infused right into the component.

g. PP blended with ABS, extremely dangerous if the component is being utilized for a security crucial application as the product has extremely little strength when flaked as the materials can not bond. Excess product in slim layer surpassing normal part geometry Mould mores than jam-packed or parting line on the device is damaged, way too much injection speed/material infused, securing force also low.

An Unbiased View of Plastic Injection Molding

Filling too fast, not allowing the sides of the component to establish up. Additionally mould might be out of registration (when the two halves do not centre properly and also component wall surfaces are not the exact same thickness). The provided information is the usual understanding, Modification: The Absence of pack (not holding) pressure (pack pressure is made use of to pack out although is the component throughout the holding time).

In other words, as the part reduces the material separated from itself as there was not Visit Website enough material in the cavity. The void can occur at any location or the part is not limited by the density however by the material circulation and thermal conductivity, but it is more probable to occur at thicker locations like ribs or managers.

Knit line/ Combine line/ Transfer line Discoloured line where two circulation fronts satisfy Mould or worldly temperatures established too reduced (the material is cool when they satisfy, so they do not bond). Time for shift between shot and transfer (to packaging and holding) is also early. Turning Distorted component Cooling is also short, product is too warm, lack of cooling down around the device, incorrect water temperature levels (the components bow inwards towards the warm side of the tool) Uneven diminishing in between areas of the part.

3 Simple Techniques For Plastic Injection Molding

125 inch wall surface density is +/- 0. The power required for this process of injection moulding depends on numerous things as well as varies between materials used. Below is a table from page 243 of the same reference as previously mentioned that best illustrates the characteristics relevant to the power needed for the most generally made use of products.In enhancement to installing assessment systems on automatic devices, multiple-axis robots can remove components from the mould and position them for further procedures. Details circumstances consist of removing of parts from the mould instantly after the components are developed, in addition to applying machine vision systems. A robotic grasps the part after the ejector pins have been extended to release the part from the mould.

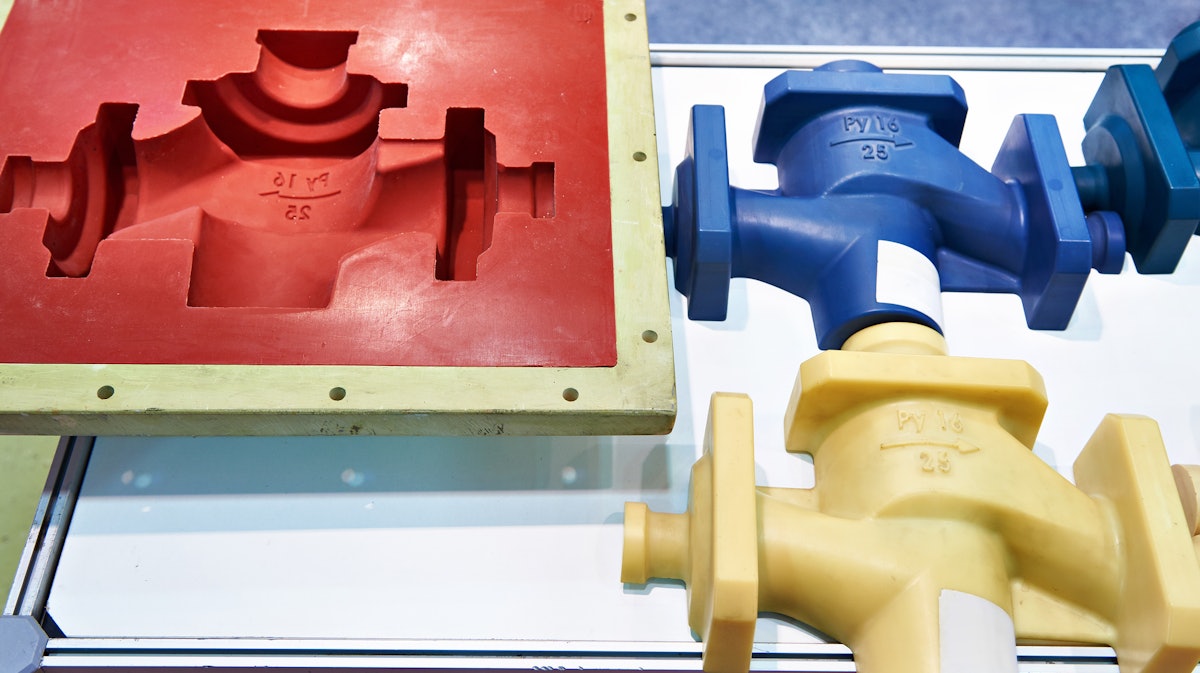

But why is shot molding maker manufacturing so effective? As well as how does it function? To discover out, let's explore the subject as well as answer every one of the essential inquiries, including what it is, the procedure behind it, its main benefits, and just how to select the right company. What is Shot Molding? is the process of making use of plastic to produce a vast array of parts as well as items.

The injection molding maker uses tailor-made molds to load learn the facts here now them out according to specifications, producing the same copies that can be tailored in a variety of methods. What's even more, injection molding is a really versatile process, enabling a wide variety of various materials as well as coatings, that makes it a preferred option in many sectors with completely various objectives and demands.

Report this wiki page